Milling plant design

Independent design and production equipment & system

- Complete set of vertical milling equipment

- Complete equipment of horizontal ball mill

- Complete equipment of classifier

- Complete set of negative pressure conveying equipment

- Electrical control system design

- DCS control system design

- PLC control system design

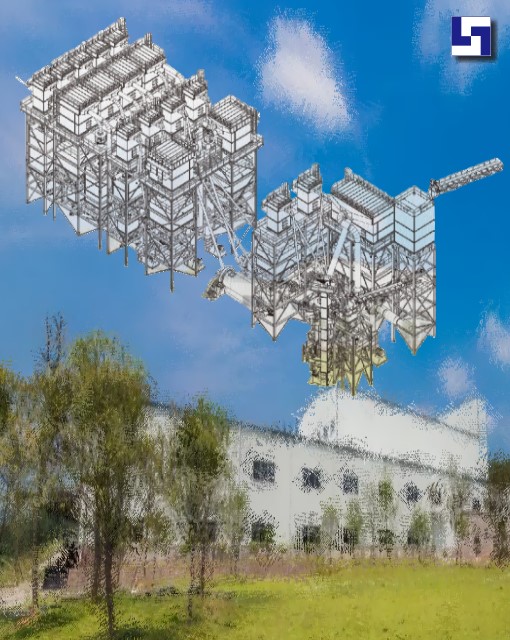

Whole mill design, production and milling process

The highest level planning, production and repair team at home and abroadThe whole mill mill equipment designed and manufactured by our company is composed of crushing system, vertical milling host system, horizontal secondary grinding system, grading and screening system, finished product packaging system and electronic control system. The raw materials are crushed by secondary jaw And after the secondary pulverization, it is conveyed to the raw material warehouse of the vertical milling machine through a belt, and is quantitatively fed to the vertical milling machine through a quantitative storage bucket for grinding, and then the classifier will grind the powder to the required fineness of the product under negative pressure Transported to the horizontal secondary grinding system. After the secondary grinding and modification are carried out at the same time, the classifier will convey the qualified fine powder under negative pressure to the classification screening system for grade screening, and the remaining material will be returned to the mill for re-grinding until the required requirements are met. The raw materials can be used in this process Maximize and reduce losses. The fine powder after screening is finally transported under negative pressure to each finished product warehouse for storage or sent to the finished product packaging system for product packaging according to product grade requirements.

After long-term research and development of milling equipment, a set of high-yield and high-efficiency production technology has been developed for the many characteristics of rough stones. This technology realizes self-grinding and self-selection. Through the frequency conversion and high-efficiency powder classifier, the product can be directly ground to meet the standard. At the same time, due to the internal fully enclosed negative pressure conveying, the fine powder products that meet the requirements can be quickly suctioned out, completely avoiding repeated grinding, greatly improving output and production efficiency, and solving dust pollution at the same time, meeting national environmental protection requirements. It can be used to grind various ores such as calcium carbonate, barium sulfate and talc.

The mill in the whole mill equipment adopts a complete set of equipment such as vertical mills, horizontal ball mills, classifiers, negative pressure conveying, etc. independently designed and produced by our company. Because the mill has a powder selection device inside, no external equipment is required. The powder separator makes the process smooth and simple. The electrical control system adopts the current advanced centralized control, DCS control or PLC control, with a high degree of automation, which effectively reduces labor costs and human operation errors, and maximizes the value and efficiency of the finished product.